- #Ultimaker cura requirements skin#

- #Ultimaker cura requirements code#

- #Ultimaker cura requirements download#

Along with that, 4 pins and 25 magnets make it easy to replace the flex plate perfectly – even with one hand. But we also don’t recommend using or adhesion structures for UltiMaker materials (except PC, ’s PC). Not only do you not need tools to pop a printed part off. A PEI-coated flexible steel build plate makes a big difference to productivity. The build stack has also been completely redesigned. To further enclose the build chamber the S7 only has one magnetically latched door. This filters the exhaust air of every print and also improves build temperature stability.

It now includes an integrated Air Manager. The UltiMaker S7 is built on the success of the UltiMaker S5 and its design decisions were heavily based on feedback from customers.

#Ultimaker cura requirements download#

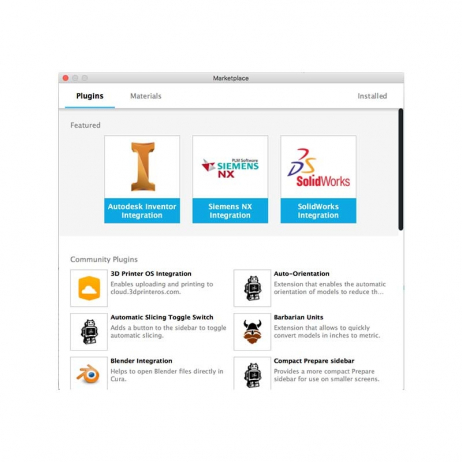

See the marketing blog, or download the latest stable release today. Got a feature that you’d like to implement? Why not make a pull request or develop a plugin? For plugin issues, please contact the plugin developer. We’ll do what we can, and we make an effort to look at everything you send us. If any odd behavior still occurs, please let us know in this thread or by opening an issue on GitHub. Thanks to the public beta we ran, we were able to catch a major bug in MacOS which caused crashing after a few slices, which is fixed in the stable release.īesides public betas, we have 2 dedicated QA people in the team, and automated tests to catch all the bugs. On a version upgrade, your packages will now follow along, and follow also actions you take using Ultimaker Cloud.Īs well as this, we’ve also switched over to a new crash reporting system (Sentry) which allows us to catch more crashes and dive into more details. When you start Cura, packages will now sync if changes are detected in your installation. Internally, we've been focused on adding integration with our new web Marketplace, so you can easily add packages to Cura from outside the software. Want to add a definition for a third-party printer? Find out how here. In addition to this, another ten third-party printer definitions have been added. Mix materials of different colors in order to print in a different color than either of your currently loaded materials. A new post-processing script can be used to mix materials if you have a mixing nozzle. When enabled, heating and pre-heating procedures act differently so that the nozzle doesn’t cool down for the stand-by temperature or the initial/final printing temperatures. A new ‘Shared heater’ checkbox has been added to the machine settings page to support printers that have one nozzle and one heater, but multiple feeders. If you load a model and change to another printer, the prefix is now correctly updated. A contribution from fieldOfview has fixed an issue where the jobname in the bottom-left of the scene is no longer made static by clicking on it. Jobnames less sensitive to being touched. When using an image with transparency, the contours of the transparent layer will be followed. Added support for images with transparency, such as PNGs.

Support for alpha channels in ImageReader. Mileage may vary, but Cura’s startup speed should see a marked improvement.

#Ultimaker cura requirements code#

fieldOfview has contributed a code optimization to load plugins faster on start. Two new settings contributed by smartavionics control this feature: ‘Skin Edge Support Thickness’ and ‘Skin Edge Support Layers’.

#Ultimaker cura requirements skin#

It’s now possible to add an extra line inside your infill that supports the edge of the skin better. This new setting contributed by smartavionics allows you to define a gap between the brim and the model for easier brim removal and reduced chance of leaving a mark on the finished piece. 4.5 contains a range of useful community contributions to give you better performance and extended features. Once again a stable release has come around.

0 kommentar(er)

0 kommentar(er)